How do you verify the design performance of Geopier® ground improvement on your site? Are you looking to ensure that your Geopier® ground improvement elements are field-tested to the appropriate stress levels?

Common questions raised by geotechnical engineers on ground improvement projects involve the load testing procedures to verify performance. These procedures must be directly connected to the Geopier design details.

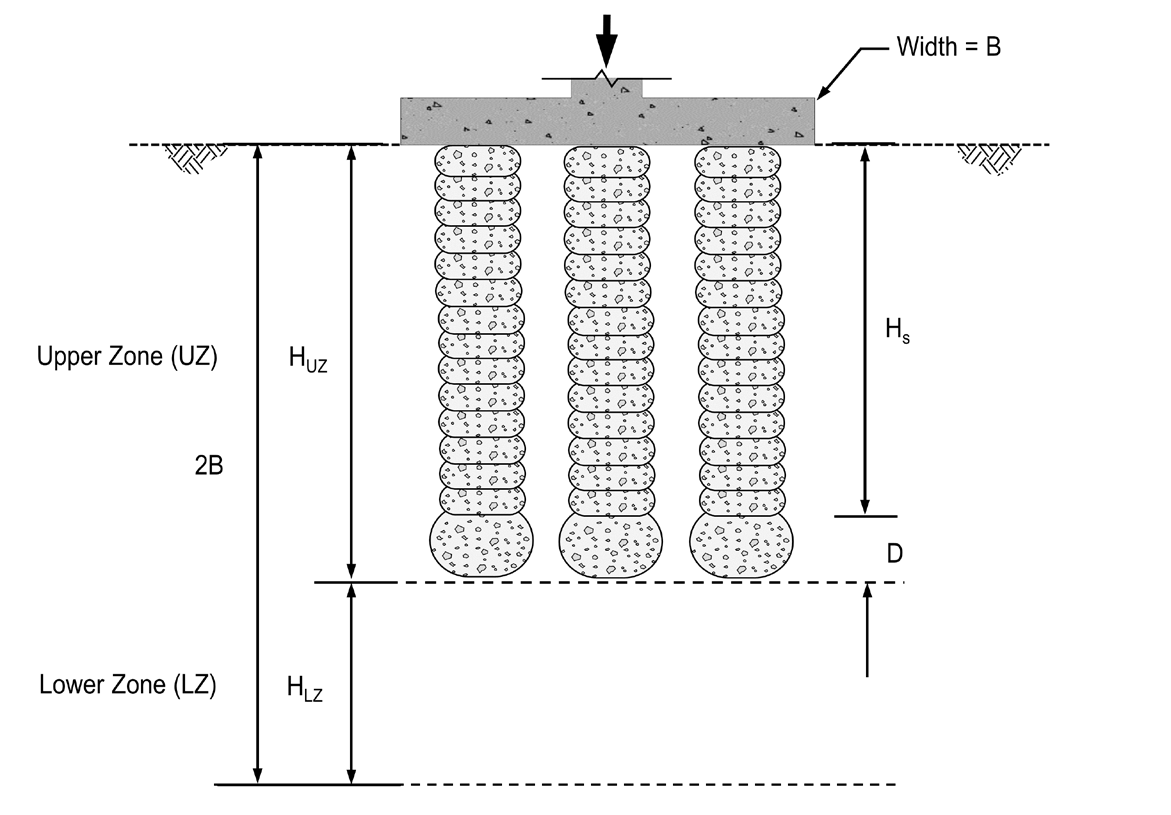

Geopier ground improvement systems are designed using a two-layer model to control foundation settlements (Figure 1). The “upper zone” is defined by the depth of the Geopier elements, and the “lower zone” is the zone of unreinforced soil below the tip of the Geopier elements subject to footing stresses.

The total foundation settlement is estimated by summing the estimated settlement in the upper zone and the estimated settlement in the lower zone. Settlements in the lower zone are computed using conventional geotechnical settlement methods. Upper zone settlements may be computed based on a spring analogy per Lawton et al. 1994, where the Geopier elements act as stiff springs and the matrix soils between the piers acts as softer springs.

Per the spring analogy, calculating foundation settlement requires knowledge of the matrix soil stiffness modulus (km) and the Geopier stiffness modulus (kg). The stiffness modulus value of the matrix soil (km) is often estimated using correlations with undrained shear strength, Standard Penetration Test (SPT) blow counts, Cone Penetration Test (CPT) tip resistances or determined from consolidation test results. The value for the design Geopier stiffness modulus (kg) is based on empirical data from historic load testing, and can be verified for a specific project by performing a Geopier modulus load test.

A modulus load test is performed on a single test pier typically constructed in the “worst” area of the site (i.e. area containing the poorest soil conditions based on the geotechnical exploration results) under conservative loading conditions. Modulus tests are conducted to at least 150% of the maximum design top of pier stress to assure a reasonable level of safety which supports long term settlement control and demonstrates that the Geopier element has adequate strength.

It is critical to perform the test to stress levels related to the maximum top of pier stress level because the stiff Geopier elements attract a significant portion of the footing load compared with the footing. Because this top of pier stress is often much higher (2 to 3 times) than the average footing bearing pressure, methods that suggest that the load test be performed to 200% of the average footing bearing pressure are inappropriate and fall short of actual field loading conditions (100% design levels).

This is such an important QA/QC topic that Geopier Foundation Company (GFC) recently issued a key paper: GFC Technical Bulletin No. 12 “Proper Load Testing Procedures to Verify Adequate Design of Geopier-Supported Foundation Systems”. It describes the importance of running field modulus/load tests based on the design top-of-pier stress (and not bearing pressure, for example). This piece is a culmination of valuable input from the local geotechnical consulting community over the past 10-15 years.