HELICAL and Geopier Foundation Company have partnered to design and install Geopier® ground improvement systems in the Northeast for over 20 years, all without there being reference to “ground improvement” in local building codes. In the absence of specific building code requirements, we have had the privilege of working with the local geotechnical and structural engineering community to address an important question on each and every project we have designed and built:

“As professional engineers, are we meeting the intent of the building code?”

This question has been at the core of countless spirited conversations over the last two decades, with subject matter including design, field testing, and construction quality control requirements for Geopier Rammed Aggregate Pier® and Rigid Inclusion ground improvement systems.

Massachusetts State Building Code

Fairly soon, there may be less to debate given that ground improvement will be incorporated into the Massachusetts State Building Code (10th Edition). Below are some key requirements that will likely be addressed in the code regarding Rigid Inclusion (RI) ground improvement:

- Evaluation and associated load testing of the allowable structural capacity of RI elements, including appropriate allowable stresses (and associated factors-of-safety) for grout and concrete.

- RI elements will likely need to be load tested to 200% design capacity.

- Evaluation of allowable shear and bending stresses on structural bearing elements such as footings and slabs. This is particularly important for features supported on RI elements since RIs attract/support much more of the footing load (multiple times more) compared to Aggregate Piers.

- Minimum number of RI elements below isolated, unbraced spread footings to help ensure footing stability.

Some Current Standards-of-Practice for Rigid Inclusion Ground Improvement

We are proud to report that the following related requirements have been incorporated into our ground improvement projects for many years now, far in advance of formal building code requirements.

1) Rigid Inclusion Load Testing to 200% Design Load – Rigid Inclusions (RIs) generally consist of unreinforced concrete (or grouted aggregate) and attract/support much more of the footing load (multiple times more) compared to Aggregate Piers (APs). Controlling failure mechanisms for RIs are different than APs. Poor RI performance could mean complete loss of footing support, as opposed to softer footing settlement response observed with APs. Because RIs behave much differently than APs, engineers look to the current building code and associated ASTM standards for guidance, such as ASTM D1143. ASTM D1143 outlines structural and geotechnical testing of piles, which have similar controlling failure mechanisms as RIs, are well studied, and have established Standards-of-Practice that address the risk of structural and geotechnical failure. For these reasons, RIs should be field-tested to similar Standards-of-Practice, including load testing to 200% design load. Testing an RI to a lower design stress per AP Standard-of-Practice is unconservative and does not adequately capture potential controlling failure mechanisms. For further detail on this topic, please refer to our April 2021 Brief “Why Field Load Testing Rigid Inclusions to 200% Design Load is the Standard-of-Practice”.

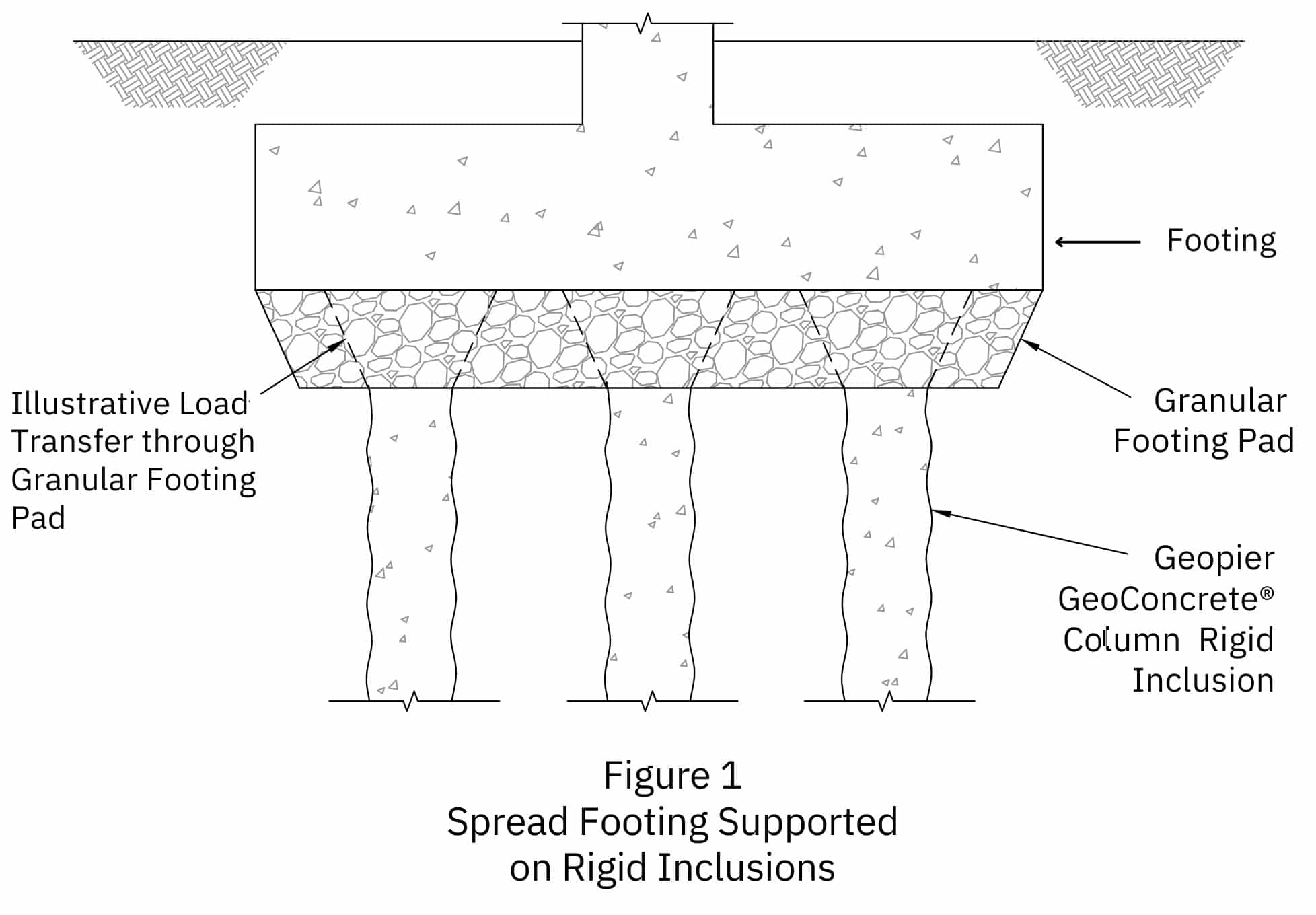

2) Allowable Shear/Bending Stresses for Footings Supported on RIs – As with all ground improvement elements (even less rigid Aggregate Piers), RI elements induce non-uniform stresses on the bottom of the footing. Compared to Aggregate Pier elements, stress concentrations resulting from RI support systems are exacerbated due to an especially high contrast in stiffness between the RI elements and the surrounding, compressible “matrix” soil. The RI elements attract more load and concentrate it in smaller areas through a granular pad. These local stress concentrations on footings differ from the uniform stress conditions assumed by the structural engineer for traditional spread footing design. As such, one-way shear, two-way shear, and bending stresses need to be checked as part of final design. For further detail on this topic, please refer to our September 2021 Brief “Rigid Inclusion Design – Early Design Coordination between the RI Design-Builder, Geotechnical Engineer, and Structural Engineer is Critical”.

3) Minimum Element Quantities for Footings Supported on RIs – Isolated, unbraced spread footings supported on RIs can be subject to rotation if there are not enough elements supporting the footing. Also, the RIs may be subject moment and shear forces for which they were not designed. As a simplified example, think of an isolated footing in unsuitable soils supported by a single RI element as analogous to sitting on a one-legged stool. The unsuitable soils provide relatively little resistance compared to the stiff RI element, thus increasing the risk of footing rotation if the RI element and column are not well-aligned, or if the footing is subject to uneven loading conditions (such as during transient loading). For these reasons, isolated, unbraced spread footings supported on RIs are often supported on a minimum of three elements.