Ductile Iron Piles (DIPs) are a simple, fast low-vibration driven pile system. Modular pile sections (each about 16.5-feet-long) are connected by a proprietary plug & drive system, eliminating the need for welding and splicing while providing a high degree of stiffness. The piles are installed with an excavator fitted with a high frequency hydraulic hammer. The sections are driven in rapid succession leading to fast and easy installation with minimal vibrations.

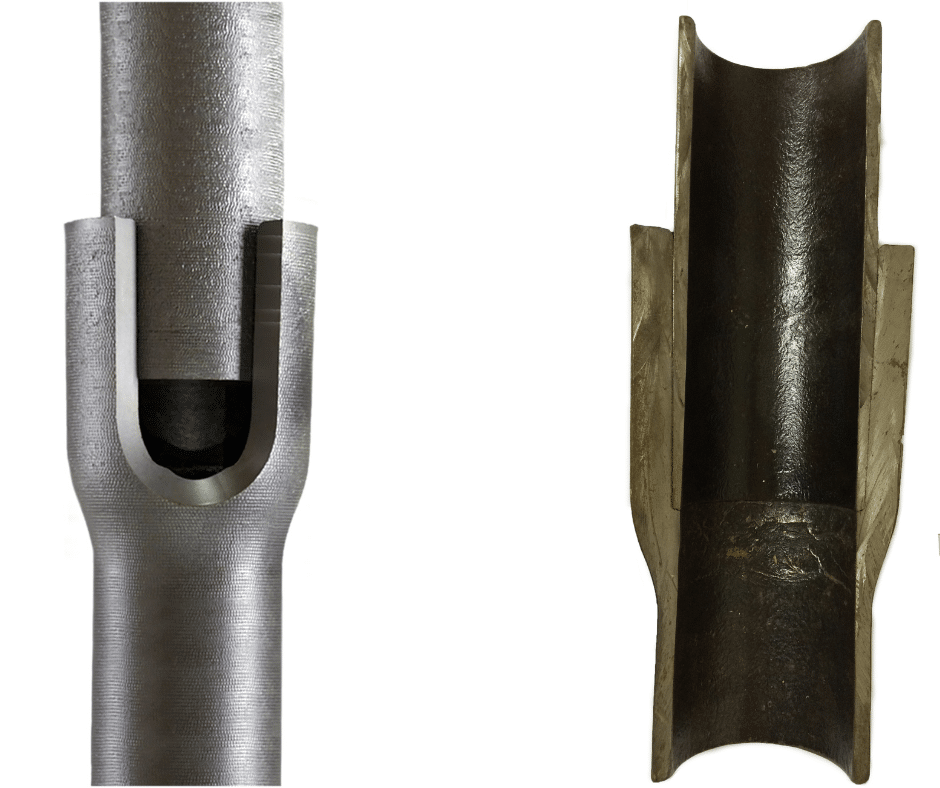

DIP sections are connected with a proprietary plug-and-drive system

DIPs derive their capacity through either end-bearing in dense soil or bedrock, or by developing frictional capacity along a grouted bond zone within competent soils. End-bearing DIPs are driven through the unsuitable soils to refusal or achieve the driving “set” criteria in the underlying dense soil, glacial till or bedrock. Friction DIPs are installed with an oversized conical grout point at the pile base. As the pile is driven, sand-cement grout is pumped through a grout shank. The grout fills the hollow pile and exits through grout ports within the conical driving point to fill the annular space between the pile section and the surrounding soil. This process encapsulates the pile in grout and forms the basis for the grouted bond zone within the surrounding competent soil to achieve design capacity.

[line]FEATURED PROJECTS

End Bearing DIP Project Example – Six-Story Residential, Everett, MA

End bearing DIPs being driven to refusal

We combined the use of Ductile Iron Piles and Geopier® ground improvement on a project in Everett, MA where vibration concerns were a factor. The project involved support of a 6-story residential structure. Soil conditions consisted of urban fill and organic soils followed by deep, stiff to soft Boston Blue Clay (BBC) extending to around 100 feet below grade. An existing 54-inch diameter sewer line was present along the eastern property line. Due to concerns with vibrations, the project team specified the use of either drilled micropiles or DIPs along the eastern foundation line. DIPs were selected based on significant cost and schedule savings over the drilled micropiles. A total of 120 piles were installed to depths on the order of 85 to 110 feet to develop capacities of 180 kips (compression) in bedrock underlying the thick BBC clay deposit. Select piles were also designed for 5 tons of lateral and tension. The piles were installed in less than 3 weeks following the completion of a successful load test performed to over 400 kips.

[line]Side Friction DIP Project Example – Spinelli Place Laboratory Building, Cambridge, MA

- Side friction DIPs installed to a predetermined design depth

- Exhumed side friction DIPs

We supported a new laboratory building at Spinelli Place in Cambridge, MA using Ductile Iron Piles due to vibration concerns along a neighboring structure. Soil conditions consisted of heterogeneous fill and organics followed by soft to stiff clay/silt, medium dense sand, and hard clay. The depth of the fill and organic soils varied between about 30 and 50 feet across a relatively small building footprint. The design featured a grouted friction pile to transfer the building loads through the fill and organics to bond in the underlying stiff clay/silt and medium dense sand. A pre-production load test program was performed. The 88-ft long, grouted test pile showed only about ¼-inch of deflection at the design load of 80 kips and was then loaded up to 280% of the design load (224 kips) and moved only about 1 inch. Strain gauge data clearly showed the transfer of loads to the bonding layer. After successful load testing, a total of 92 production piles were installed. Pile lengths ranged from 64 to 85 feet across the site. The installation was completed in less than 2 weeks.