AGGREGATE PIER (AP) LOAD TESTING STANDARD-OF-PRACTICE

The Standard-of-Practice for load testing aggregate piers (APs), such as Geopier Rammed Aggregate Pier® elements, consists of a full-scale, single-element load test that is loaded to 150% of the element’s maximum top-of-pier design stress to verify the AP design stiffness. Testing AP elements to 150% maximum design stress is appropriate for several reasons:

- APs are comprised of compacted aggregate, so building code requirements for material strength testing to confirm adequate “structural” capacity are not applicable.

- Testing needs to be conducted far enough past 100% maximum stress to confirm that the response of the AP is elastic (i.e. to check bulging vs. plunging at high stresses).

- With APs, much of the footing load is carried by the improved/surrounding matrix soil. Thus, poor performance would mean a softer response, but not complete loss of footing support.

Most AP ground improvement performance specifications written by geotechnical engineers today appropriately include the 150% test load requirement for the reasons described above. Refer to Geopier Foundation Company Technical Bulletin 12 for further detail on proper AP load/modulus testing.

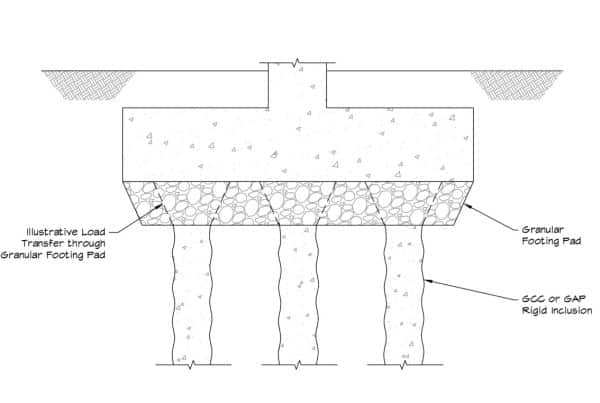

RIGID INCLUSION (RI) LOAD TESTING STANDARD-OF-PRACTICE

Rigid inclusions (RIs) behave much differently than APs:

- RIs are, well….rigid (it’s in the name)!

- RIs consist of unreinforced concrete or grout, so testing criteria to confirm adequate “structural” capacity are applicable (i.e. building code requirements for material strength testing).

- RIs are much stiffer (multiple times more!) compared to APs.

- RIs attract/support much more of the footing load (multiple times more!) compared to APs.

- Controlling failure mechanisms for RIs are different. Poor performance can mean complete loss of support, as opposed to softer settlement response observed with APs.

Because RIs behave much differently than APs, engineers look to the building code and associated ASTM standards for guidance, such as ASTM D1143. ASTM D1143 outlines structural and geotechnical testing of piles, which have similar controlling failure mechanisms as RIs, are well studied, and have established Standards-of-Practice that address the risk of structural and geotechnical failure. For these reasons, RIs should be field-tested to similar Standards-of-Practice, including load testing to 200% design load. Testing an RI to a lower design stress per AP Standard-of-Practice is unconservative and does not adequately capture potential controlling failure mechanisms.

While there are currently no specific building code requirements for AP and RI ground improvement, we anticipate that future code amendments will likely reflect these standards for field load testing. As such, performance specifications written today can (and should) be reflective of this practice and enforced during the design submittal and field-testing process. Why risk the consequences of performing an inadequate load testing program that does not meet the current Standard-of-Practice and probable future code requirements?