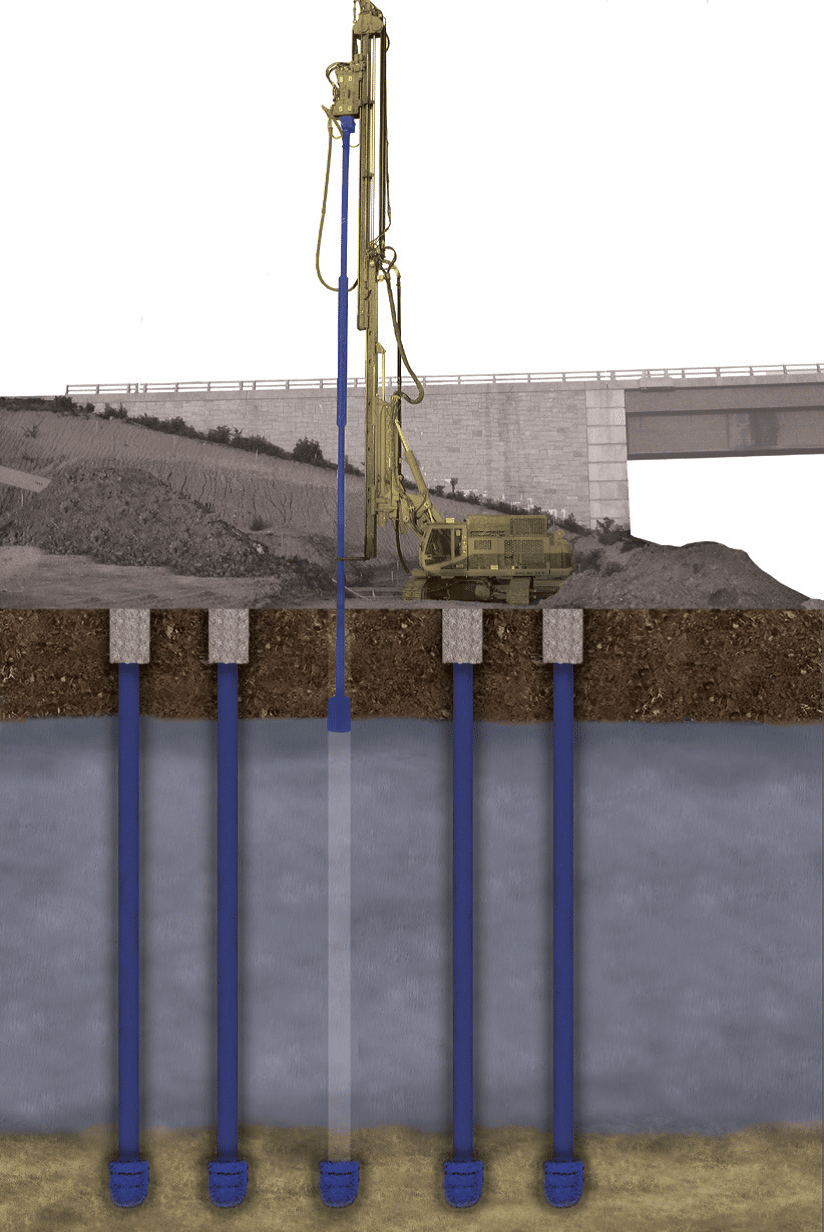

Geopier GeoConcrete Columns (GCCs) are high-stiffness, rigid inclusion ground improvement elements. They work together with surrounding soils to support heavy applied footing loads and control settlement on sites with weak and/or compressible soils, such as soft clays or organics. They are constructed with a patented steel displacement mandrel that produces little to no spoils and does not require casing or dewatering.

GCCs are a cost-effective replacement for deep foundations including driven piles, drilled shafts, pressure injected footings (PIFs) and augercast piles.

View the Holiday Inn Chelsea installation footage where GCCs were installed to depths of nearly 60 feet.

Geopier GeoConcrete Columns Can Address a Number of Geotechnical Challenges

- Heavy structural loads over soft soil layers

- Soft silts and clays

- Soft organic soils such as peat or organic silt

- Contaminated soils

- Soils below the groundwater table

Construction Process

- The steel displacement mandrel is aligned vertically and placed on the ground at the GCC location.

- The mandrel is charged with concrete under controlled pressure.

- The mandrel is vibrated into the ground to the desired GCC depth using high-frequency, low-amplitude energy. The patented design prevents soil from entering/clogging the mandrel. This process displaces the surrounding soil laterally, resulting in some densification of the soil.

- During driving, concrete is continually pumped into the mandrel. Concrete pump strokes and system pressure are closely monitored to determine the volume of concrete that is being installed.

- After reaching the design depth (generally dense soil or bedrock below the soft soil layer), concrete pumping continues while the mandrel is raised and lowered repeatedly. The mandrel head engages the concrete and forces it downward and outward to form a bottom “bulb”, or expanded base.

- After forming the expanded base, the mandrel is slowly raised to form a continuous GCC shaft that extends up to just below the bottom-of-footing level.

- Because of their high stiffness, GCCs attract relatively high stresses that must be transferred between the bottom of the footing and the top of the GCCs. As such, an engineered structural fill pad (“footing pad”) is designed and installed on top of the GCCs to help transfer footing stresses to the GCCs and surrounding soil.

How Geopier GeoConcrete Columns Work

Geopier GeoConcrete Columns are high-stiffness, rigid inclusion ground improvement elements that work together with surrounding soils to transfer heavy footing loads below soft soil layers down to a suitable bearing layer. The GCCs, combined with an engineered footing pad, provide an improved subgrade for traditional shallow footing support.

Key Advantages

- Replaces more expensive deep foundations such as driven piles, drilled shafts, pressure injected footings (PIFs) and augercast piles.

- No spoils are generated during the displacement process.

- Does not require casing.

- Dewatering is not required.

- Treatment depths can exceed 50 feet.

- Rapid installation allows for shorter schedules.

- Designed, built and managed with local engineering, manpower and equipment.

Recent Projects

- 100 College Street, 12-Story Building – New Haven, Connecticut

- Harbor Place 6-Story Building – Haverhill, Massachusetts

- Stormwater Storage Tanks – Everett, Massachusetts