Ductile Iron Pile Solution Reduces Foundation Installation Schedule by More Than 2 Weeks

Project: Mystic Avenue Single-Story Building

Location: Medford, MA

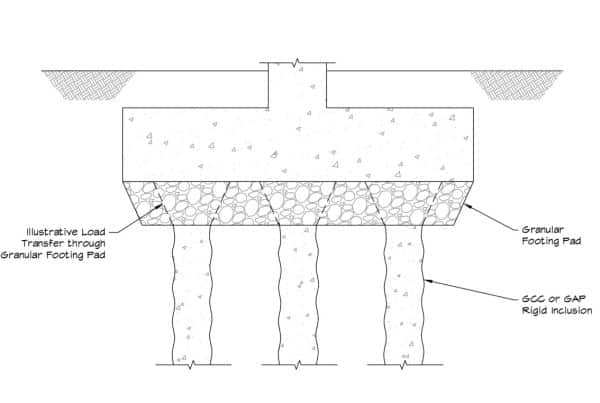

An existing single-story structure located on Mystic Avenue in Medford, MA was undergoing extensive renovation work to accommodate a new tenant. The existing building slab was in poor condition because of settlement attributed to the presence of urban fill and peat to depths up to 15 feet below grade. Plans called for removal of the slab-on-grade and replacement with a pile-supported structural slab.

Initial recommendations for compression capacity included typical options for interior work including drilled micropiles and helical piles. Both of the systems were planned to develop capacity after penetrating the 18 feet of fill and organics and terminating in the underlying stiff to soft clay. The initial design specified drilled micropiles with at least 2 rounds of post-grouting to achieve a 20 ton compression capacity.

After performing an additional deeper boring to confirm the depth to competent till/rock, Helical provided a value-engineered solution to work in the 20 feet of overhead clearance using Ductile Iron Piles (DIPs) to help reduce the installation duration and provide cost-savings. The Ductile Iron Pile option consisted of Series 118 (118 mm diameter) installed to penetrate through the peat, organic and clay to terminate on dense glacial till/rock. The DIP solution matched the 20 ton compression capacity and replaced the micropiles on a 1:1 basis.

Installations were performed by cutting each 5 meter modular pile section and using couplers to efficiently splice the piles within the 20-ft of headroom. A total of 42 piles were installed to depths of over 85 feet in only 7 days to provide cost savings and most importantly, reduce the foundation installation schedule by more than 2 weeks.

Do you have a project requiring a cost-efficient deep foundation solution that requires quick installation?

Contact us today for a project assessment.