June 2015 | By Paul Fournier

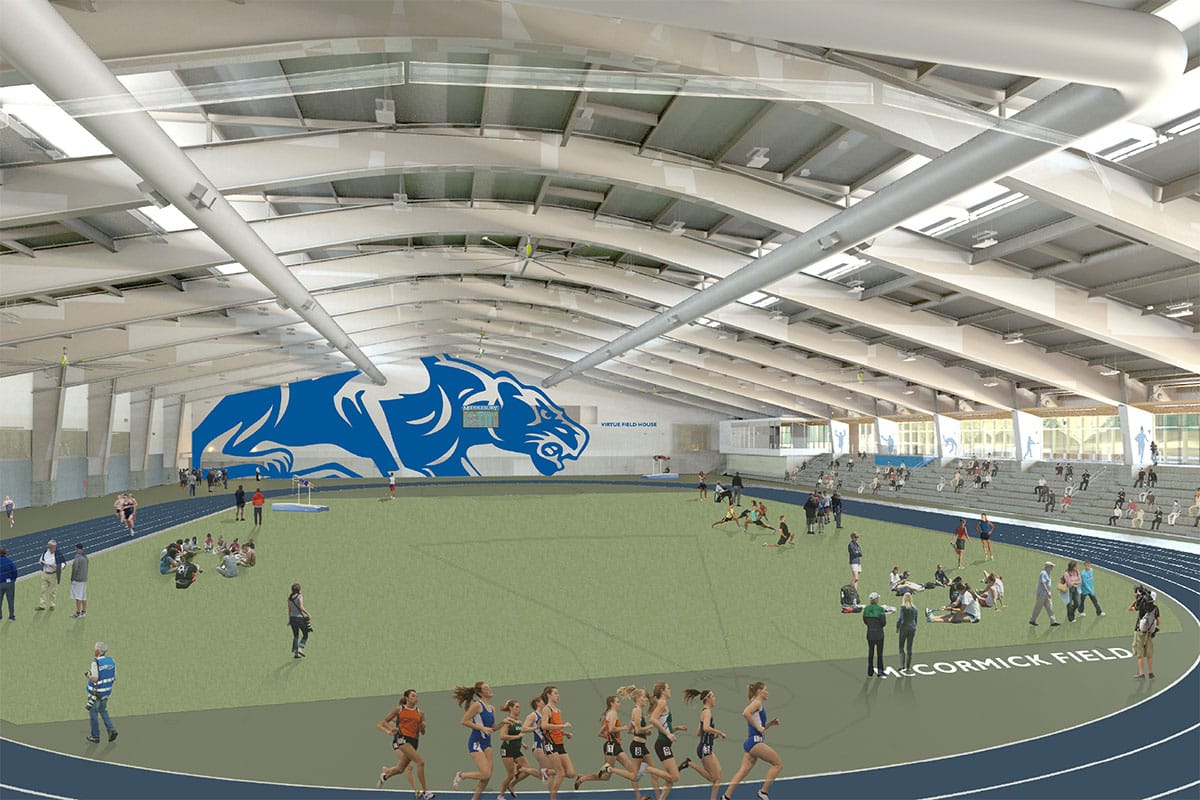

2015 A massive steel framing system has provided a 240-foot-wide, column-free interior space at Middlebury College’s newly completed field house, enabling the 215-year-old Vermont institution to host regional and NCAA indoor track and field events for the first time in its history.Designed by Boston-based Sasaki Associates and built by PC Construction of South Burlington to replace a smaller, air-sup-ported structure, the new $29 million facility owes its spacious interior to 10 huge steel portal frames. Structural engineers LeMessurier Consultants of Cambridge, Massachusetts, designed the giant 60-ton roof beams, which are equidistantly spaced along the structure’s 300-foot length. Canatal Steel custom-fabricated the portal frames using a 2-1/2-inch thick steel plate, dividing each of the structural elements into five sections – four straight sections and an arch section. Due to their great size and weight, only two of the 6-foot-tall sections could be carried by flatbed trucks at a time for the haul to the job site.

Aggregate Piers Improve Ground

Despite the extraordinary width and depth of the footings, there could have been some unacceptable structure settlement due to the presence of low bearing capacity soil at the north end and east side of the building site. To prevent this, the construction team decided to have a ground improvement system installed that would support the building foundation and limit the long-term building settlement to within acceptable criteria.Conceived by Design/Build Geotechnical LLC and Geopier Foundation Company, the ground improvement system involved the installation of Impact Rammed Aggregate Piers to support the building’s footings. In this system, a pier is formed by pushing down through existing soil to create a cavity, followed by placing crushed stone into the cavity in 12-inch compacted layers. The result is a very dense stone column capable of carrying much greater loads than the original soil.Helical Drilling Inc. of Braintree, Massachusetts, was selected to install the piers. For this highly specialized operation, the company used an ABI MOBILRAM TM 13/16 telescopic mast mounted on a soilmec SR-30 crawler carrier.

The new $29 million facility owes its spacious interior to 10 huge steel portal frames.

According to Helical Drilling, in this process a cavity is created to full depth by pushing a hollow mandrel and tamper foot through existing soils using a relatively large static force augmented by impact energy. Pier depths normally range between 10 and 55 feet. This method is said to eliminate spoils since all penetrated soils are displaced laterally. A sacrificial cap prevents soil from entering the tamper foot and mandrel.After driving to design depth, the hollow mandrel serves as a conduit for the placement of aggregate. The aggregate is placed inside the mandrel and the mandrel is lifted, leaving the sacrificial cap at the bottom of the pier. The tamper foot is lifted approximately 3 feet and then driven back down 2 feet, forming a 1-foot-thick compacted lift. This procedure is repeated continuously until the desired length of pier is reached.In low load-bearing soil such as that found at the field house site, grout made with neat Portland cement and water is added to the stone to help bind the aggregates together. The cement grout is placed into the hollow mandrel, followed by the aggregate. Ramming the grouted aggregate is said to densify aggregate vertically and the patented beveled tamper foot forces aggregate laterally into cavity sidewalls, which strengthens the soil surrounding the piers. Helical Drilling installed more than 500 of the 20-inch-diameter piers. The depths of the piers varied between 10 feet and 35 feet, depending on design requirements.

Retaining Wall Shields Arena

Elaborate Steel Erection Sequence

Once the footings were formed, placed and cured, crews erected the 36-foot-tall steel columns, 10 to each side, in preparation for the portal frame lifts. Steel erection was performed by CCS Constructors Inc. of Morrisville, Vermont, using three cranes – two lattice boom Link Belts (275-ton and 235-ton) and a 290-ton hydraulic Grove. According to PC Construction’s Project Manager, Rich Leclerc, the steel erection sequence was an elaborate one. At first, the construction team had decided to erect the portal frames using three cranes and two 50-foot shoring towers. Five sections of the portal frames were assembled together on the ground into three separate pieces – two joined straight sections for the west side, the arch section for the middle of the span, and two joined straight sections for the east side. Workers joined the sections together with splice plates and high-strength bolts on the frame webs, and with continuous welds across the top and bottom flanges.The Link Belt cranes lifted the straight pieces, placing one end on the shoring tow-ers and holding the pieces while ironwork-ers welded and bolted the other ends to the respective columns. Next, the Grove crane raised and held the arch section between the two straight pieces while it was connected to them.Leclerc said that crews followed this procedure for the first two portal frames, but changed sequences for the eight remaining frames.This involved just the two Link Belt cranes and one shoring tower. On the ground, workers assembled the five-sec-tion portal frames into two pieces – two joined straight sections for the west side, and two joined straight sections plus the arch section for the east side. One Link Belt crane raised the three-sec-tion piece and placed it on the shoring tower while workers connected it with the east side column. The other Link Belt raised and held the west side piece while it was joined with the column and the end of the arch section, completing the portal frame.As each portal frame was completed, it was joined to the preceding frame with steel purlins, creating an increasingly stable, three-dimensionally braced structure. In compliance with job specifications, a shoring tower was always in place under each of the two most recently erected portal frames. Leclerc noted that a total of 3.5 million pounds of structural steel was required for the new field house.

Big Enough for NCAA

Download the original article here.