When geotechnically unsuitable soil conditions exist, ground improvement methods such as Geopier® Rammed Aggregate Pier® (RAP) elements and GeoConcrete® Column (GCC) rigid inclusions are often specified as economic alternatives to removal/replacement or deep foundations (piles). Unsuitable soils, such as undocumented fills, are generally given their unflattering moniker because under new construction loading, they could:

- Have a soil bearing (rotational shear) failure, or

- Settle excessively

Of these two undesirable outcomes, settlement control is almost always the controlling factor in ground improvement feasibility, design, and cost. Having service-level structural loading (not allowable soil bearing pressure) for ground improvement applications is fundamental to accurately calculate settlement. Two examples are below to help further illustrate. The first example shows how actual service level loads are required to evaluate total and differential settlement performance. The second example shows that not having actual loads could divert the project away from a shallower, more cost-effective ground improvement solution and onto more expensive solutions.

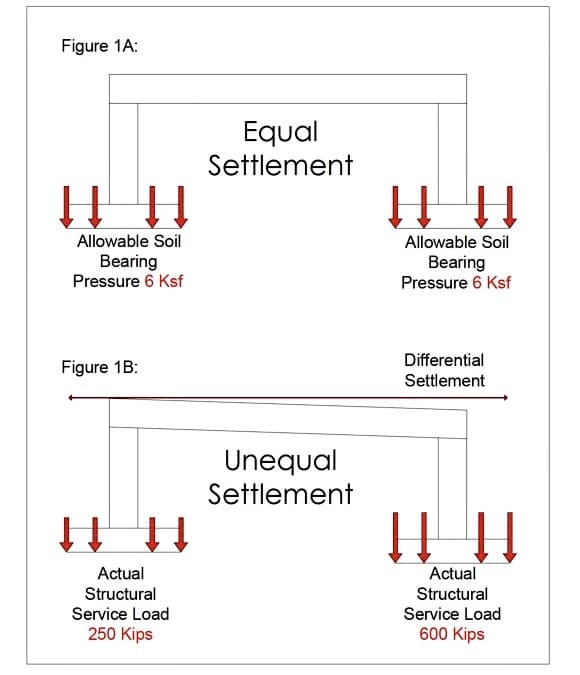

Example 1 – Consider Figure 1A where two identically-sized footings (10 feet x 10 feet plan view) are evaluated for settlement using the project-specified 6 kips per square foot (ksf) maximum allowable soil bearing pressure. When settlement calculations are performed, the analysis indicates that both footings have the same applied load (10’ x 10’ x 6 ksf = 600 kips) and therefore the same amount of total settlement (and no differential settlement).

However, consider Figure 1B for those same two identically sized 10’x10’ footings. One footing is in a braced frame and was oversized for uplift resistance. It has actual service loading of only 250 kips. The other footing has an actual service load of 600 kips.

When settlement calculations are performed using the actual service loading, the analysis shows that the footings experience differential settlement. With this critical information, the ground improvement designer can adjust the ground improvement design to provide more equal settlement performance and less differential settlement.

In summary, without accurate service loads, the ground improvement designer cannot tailor their design to provide the best possible total and differential settlement performance.

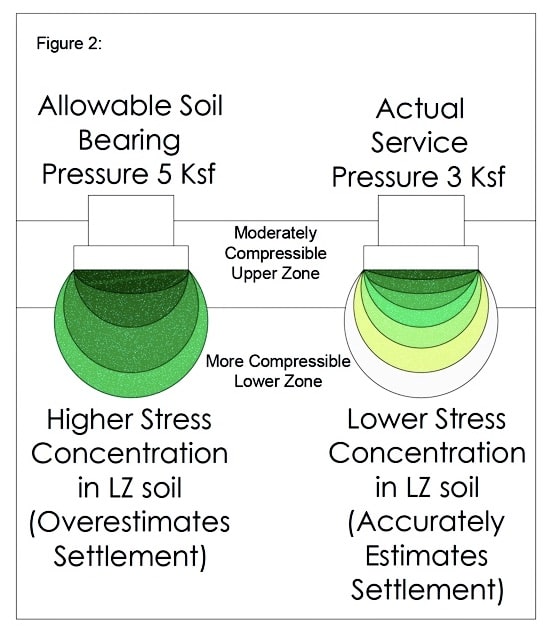

Example 2 – This next illustration (see Figure 2) shows how preliminary feasibility exercises that do not include best-estimates of footing/mat service loads could divert otherwise successful projects away from cost-saving ground improvement onto more costly solutions.

Consider a large mat foundation supporting an elevator or shear wall. In this example, the mat on the left is evaluated for settlement using the project-specified 5 ksf maximum allowable soil bearing pressure. The identical mat on the right is evaluated for settlement using the actual service contact pressure of 3 ksf. The simplified soil profile consists of “moderately compressible” upper zone soils overlying the “more compressible” lower zone soils.

Note in the illustration how the (left) mat loaded to the project-specified 5 ksf maximum allowable soil bearing pressure induces more stress beyond the “moderately compressible” upper zone soils into the “more compressible” lower zone soils. This simplified soil profile is quite representative of many typical soil profiles in the Northeast. When settlements are calculated for these identically sized foundations, the effect of the increased stress on the “more compressible” layer is often substantial. In many cases, the increased settlement from this simplified loading assumption drives the project from a shallower, more cost-effective ground improvement solution and onto more expensive solutions like deeper ground improvement or deep foundations (piles). In summary, using allowable soil bearing pressures to calculate settlement can yield misleading conclusions regarding foundation support viability and/or lead to Owner cost premiums.