Amtrak Railroad Section Support

Location: Providence, RI

Technique: Geopier GP3® Rammed Aggregate Pier® Elements

Introduction:

The project included 520 linear feet of a depressed railroad “boat” section at a congested site with relatively low overhead restrictions.

Geotechnical Challenges:

The site had challenging subsurface conditions, including a 4- to 13-foot-thick layer of unsuitable granular fill underlain by a layer of soft peat and organic silt that was up to 10-feet-thick. Groundwater levels were encountered at depths ranging from 4 to 11 feet. Supporting the railroad section over the existing unimproved fill, peat, and organic silt would have resulted in excessive settlement.

Geotechnical Design and Construction Solution:

The project team evaluated a number of foundation support solutions including conventional foundation construction after over excavation and replacement, deep foundations (piles), and conventional foundation construction after Geopier GP3® Rammed Aggregate Pier® (RAP) ground improvement. The Geopier GP3 RAP system was selected as the best approach and was designed to provide an allowable bearing pressure of 4,000 psf and limit settlement to less than ¾ -inch (½ -inch at utility crossings). Lateral soil resistance was also a primary design consideration. The Geopier GP3 RAP system reduced construction costs, provided a faster construction schedule, limited noise and vibration impacts, and facilitated “conventional” foundation construction.

Ground Improvement Construction:

Helical installed over 450 RAP elements that fully penetrated through the unsuitable fill and organic soils and into underlying natural granular soils. The design/build solution was completed on schedule, within budget, and with no significant post-construction settlements at a considerably lower cost compared to overexcavation and replacement or deep foundations.

Quality Assurance and Control:

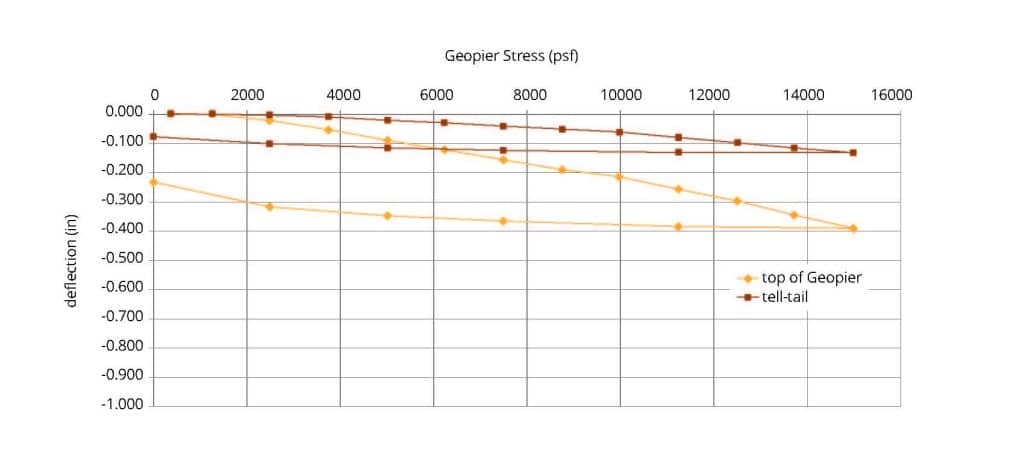

Helical’s crew included a full-time Quality Control person to oversee all Geopier GP3 RAP testing and production. A full scale modulus test was conducted on a non-production RAP test element to 150% of the RAP element maximum design stress. The testing results indicated a deflection of about ¼-inch at 100% design stress and a corresponding RAP stiffness of 303 pci. This RAP stiffness was double the design stiffness of 150 pci, indicating superior performance of the Geopier ground improvement system.