Secant pile wall installed at 170 West Broadway

Several QA/QC measures were implemented to help guarantee successful construction of the secant pile wall installed at 170 West Broadway. Prior to construction, Helical performed five exploratory soil borings to supplement the subsurface exploration work that was performed during previous stages of project development. The combined information thoroughly defined subsurface conditions to better predict productivity rates and select the most appropriate drill tooling.

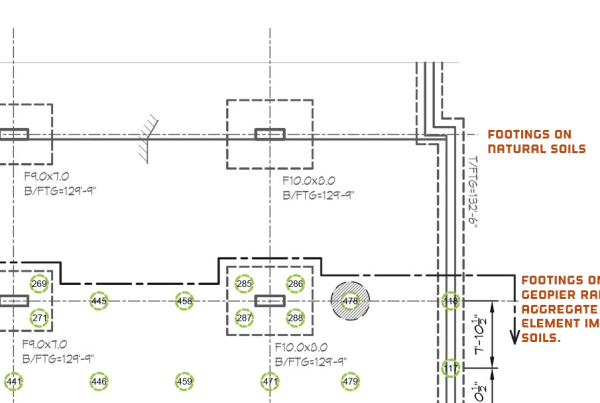

A reinforced concrete guide beam was cast along the perimeter of the building footprint to serve as a rigid template for secant pile wall construction. The guide beam helped provide proper wall alignment with a high degree of accuracy, as required by the project’s architectural and structural layout.

Helical’s field-based QA/QC program included measuring and adjusting the fluidity (slump) of the concrete mix on a truckload-by-truckload basis to ensure high quality and pumpability. Likewise, the field crew routinely obtained concrete cylinder specimens and submitted them for laboratory testing to ensure compliance with the required design compressive strength.

Other critical parameters were continuously monitored using Helical’s on-board automated monitoring system including rate of drilling, depth of pile penetration, pile verticality, rate of concrete pumping, and rate of auger withdrawal.