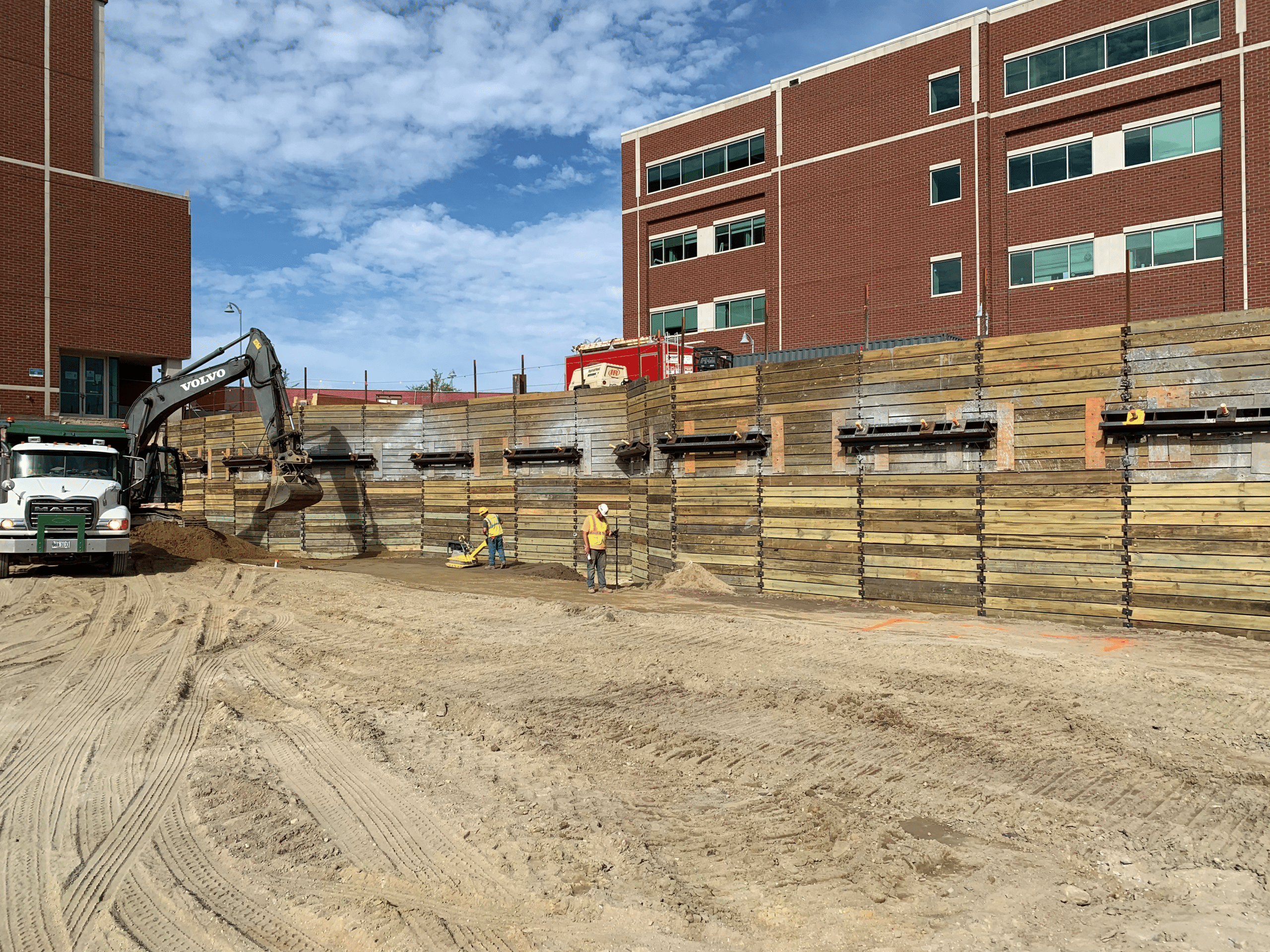

Soldier Pile and Lagging Walls

Solider pile and lagging (SP&L) earth retention systems consist of closely-spaced vertical steel piles with horizontal lagging installed between the piles. Soldier piles are installed by: 1) driving (or vibrating) steel H-piles or 2) drilling steel pipe into the ground prior to excavation. Piles are installed at relatively close spacings (typically about 4 to 8 feet). Once pile installation is complete, lagging installation and excavation work can begin. The excavation work proceeds in concert with lagging installation in small segments (typically about 2 to 4 feet vertically). The lagging, typically consisting of timber, is installed horizontally between the vertical piles. The process of excavating and lagging continues segmentally as the total excavation depth increases. For shallow excavations, the SP&L system is often cantilevered. For deeper excavations, the SP&L system can be combined with tiebacks or internal bracing for increased system stability. Compared to driven sheet pile walls, SP&L earth retention systems can offer the following advantages: 1) more design flexibility with wall alignment, 2) no vibrations (when drilled steel pipe soldier piles are used), and 3) the ability to penetrate relatively dense or obstructed ground conditions (again, when drilled steel pipe soldier piles are used).