Vibratory Probe Compaction (VPC)

Vibratory Probe Compaction (VPC) is a deep ground improvement method that densifies loose, clean granular soils in-place (above or below the groundwater table). VPC is sometimes an economical alternative to other ground improvement methods or removal/replacement. VPC is a dry process that does not require (messy) water jetting, earth berms, or other premium site costs.

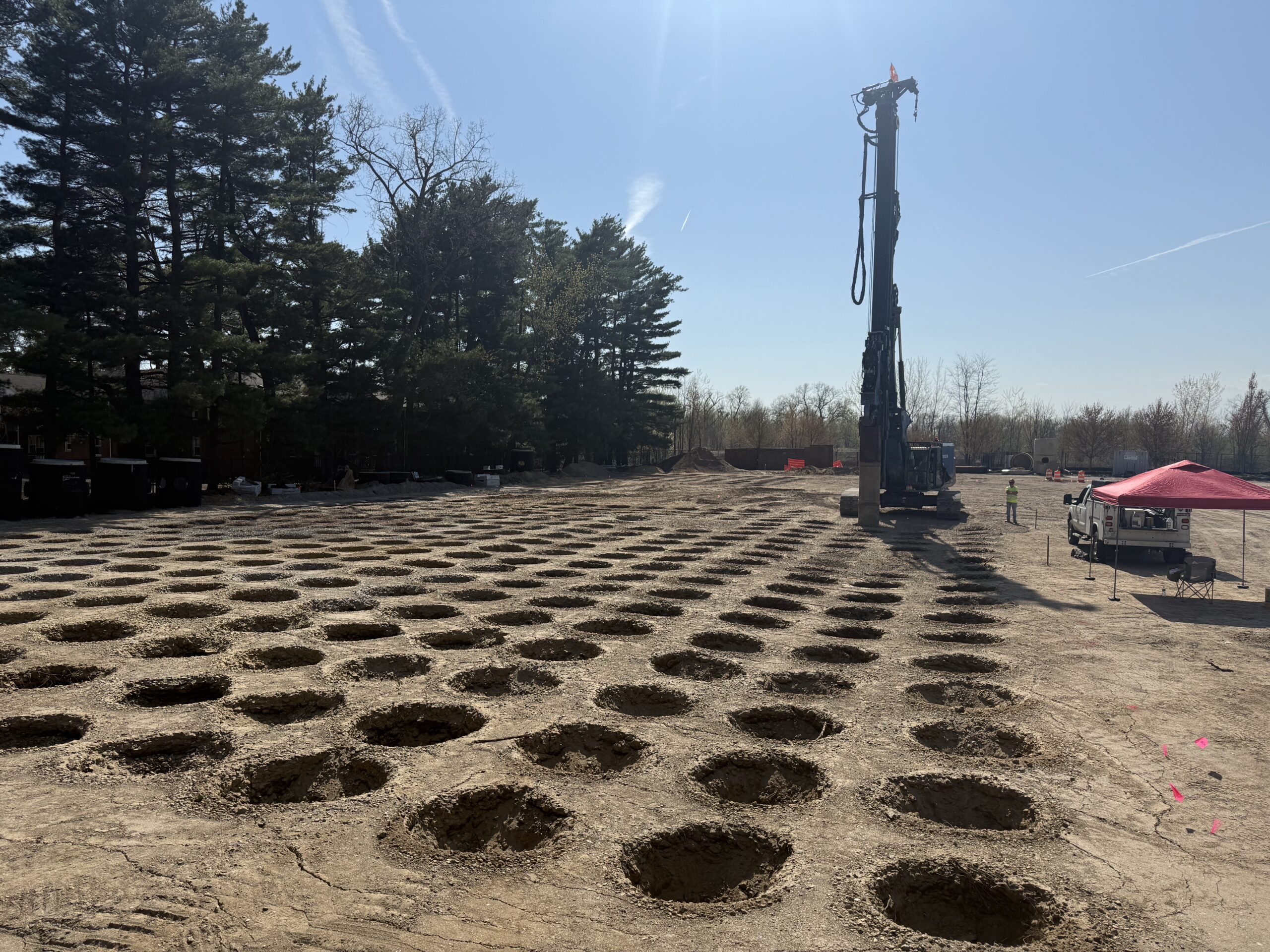

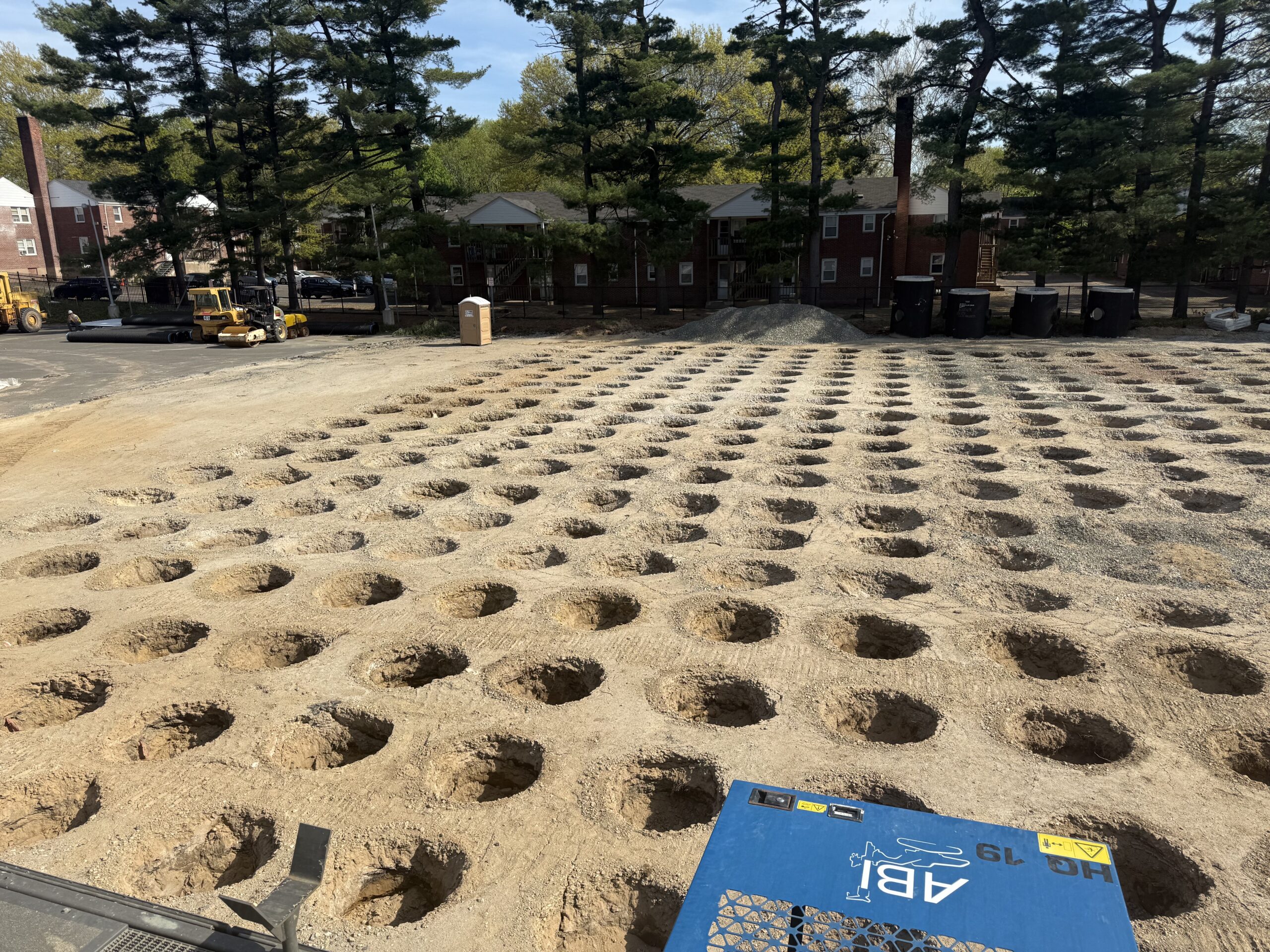

VPC consists of repeatedly driving and extracting an open-ended, large-diameter steel pipe into the ground using a large, high-frequency vibratory hammer. The probe has plate straps (ribs) welded to the outside surface to help transfer vertical vibrations to the granular soil to be densified. The vibrations and lateral displacement cause the soil particles to rearrange into a denser configuration. VPC is carried out in a grid pattern across the site; each probe location receives multiple cycles of treatment depending on the desired results and the site response during driving. Soil density is increased uniformly across the site, resulting in improved settlement control and enhanced bearing capacity. The effectiveness of VPC treatment is typically evaluated by comparing pre-treatment and post-treatment SPT N-values.

Following VPC treatment, the site contractor strips the treated area to the bottom of any surface craters that develop during probing and then performs heavy surface compaction (with vibratory rollers) to prepare the site for foundation work.