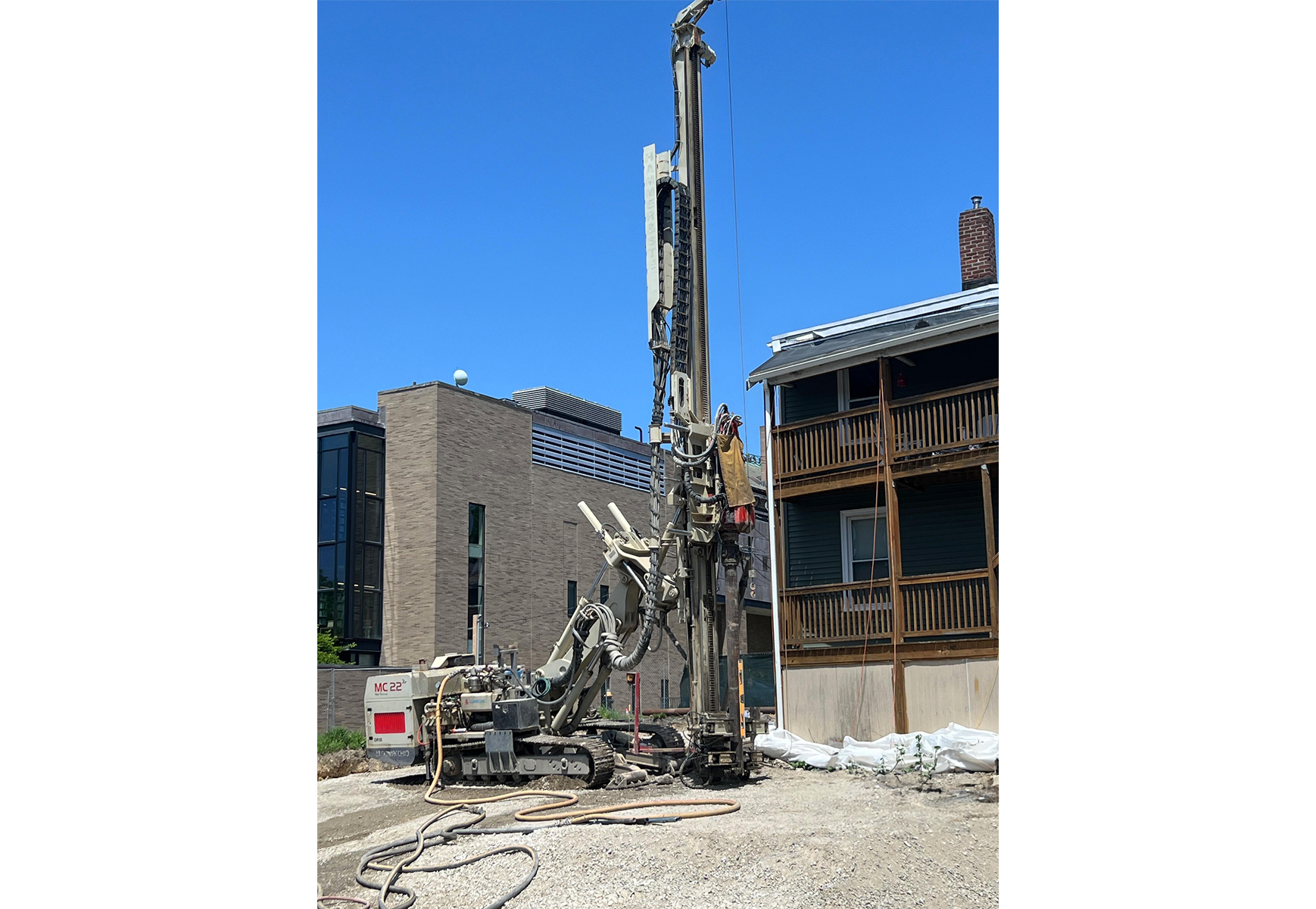

Drilled Micropiles

Drilled micropiles (DMPs or mini-piles) are high-capacity, small diameter, drilled deep foundation elements that are used to support new foundations or underpin existing foundations. They generate only minimal vibrations and can be installed with only 8 feet of overhead space and in other limited-access situations. DMPs generally consist of a combination of steel casing, threaded bar, and grout. They derive their geotechnical capacity through side friction between the grout and surrounding soil or bedrock. DMP construction methods vary depending on project-specific conditions, but are generally installed by: 1) advancing the steel casing to a predetermined design depth using rotary-wash or compressed-air drilling methods, 2) filling the casing with grout, 3) inserting a central threaded bar through the grout, and 4) withdrawing the casing to create a bond zone between the grout and surrounding soil or bedrock. Some casing is typically left in the ground permanently to facilitate structural connections, for seismic design considerations, or for other design considerations.

DMPs are particularly useful in limited access situations, adjacent to vibration-sensitive structures, and when penetration through relatively dense and/or obstruction-laden fill is required. In cases where the fill is not particularly dense, but limited access and vibrations are still a concern, Ductile Iron Piles or Helical Piles can often be cost-effective alternatives to DMPs.